Barilla: A mini history

Share

1. Alkaline Ash

Nablus soap is known for its unique cooking process, where the soap is heated for a week or more to react soda with olive oil and water. This reaction requires an alkaline soda powder, which for the first 1000 years, was primarily made from barilla plant ashes and lime (calcium oxide, or super-heated limestone).

People have long used wood ashes or potash as a cleaning agent, with hardwood ashes being more effective than softwoods due to their high pH. However, for soapmakers, creating alkaline water of a specific strength is crucial to interact effectively with the acidic oil base. To make a hard soap, a good salt content is needed in the potash, which must be used in large quantities to create a strong lye solution. Soapmakers, glassmakers, and other artisans needing strong alkaline substances relied on caustic potash, also known as caustic soda.

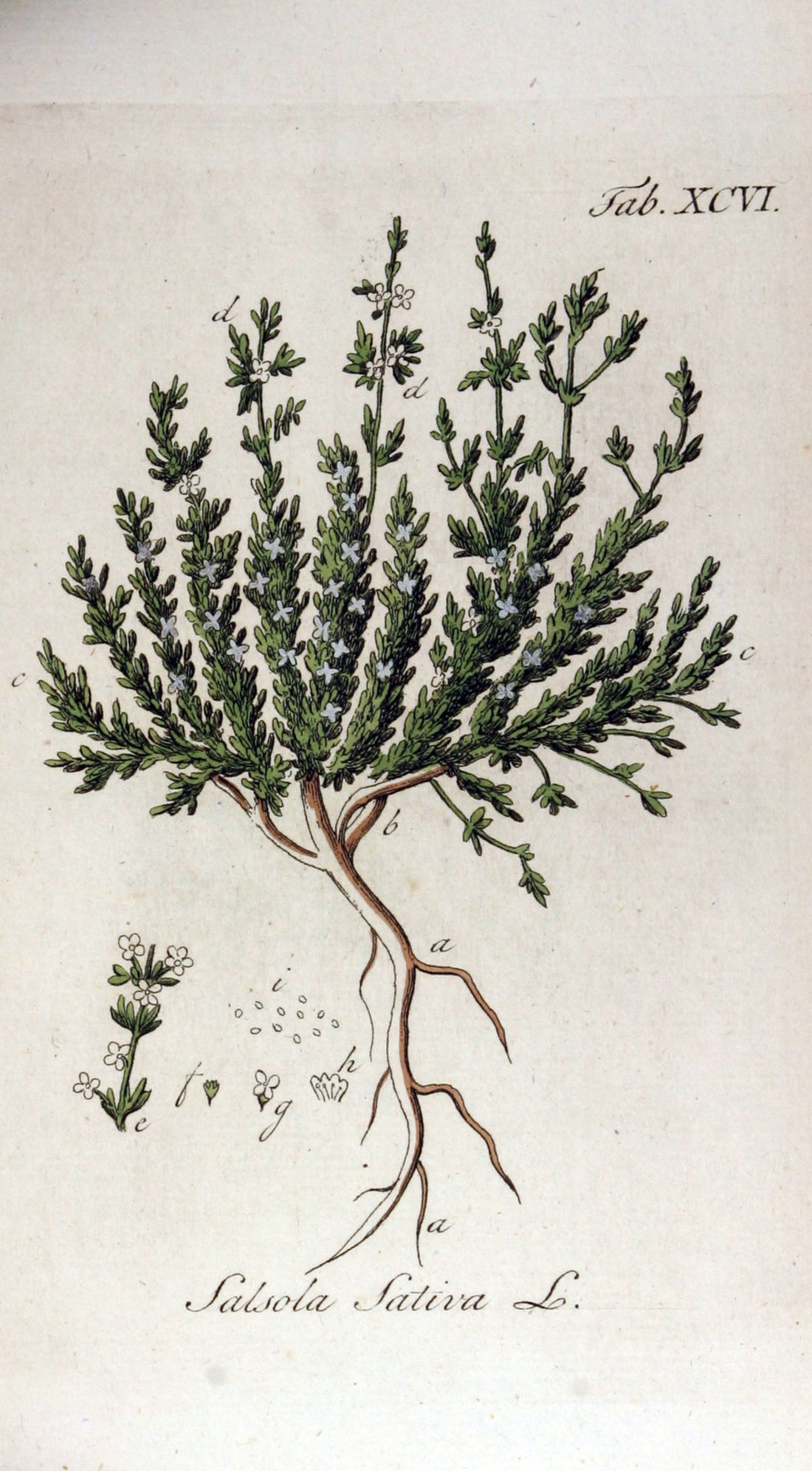

Mediterranean artisans discovered that ashes from saltwort plants like barilla were superior to hardwood ashes for making caustic potash. Barilla, scientifically known as Salsola soda and Salsola kali, is particularly effective due to its high content of sodium carbonate, which produces a strongly alkaline, salt-bearing potash. A thousand years ago, it held significant economic importance in the Mediterranean. In the 1800s in Spain, smuggling barilla seeds without proper permits was punishable by death. In Nablus, the trade in barilla ashes, called qilw, was monopolized by local Bedouin.

2. Qilw in Nablus

The Brown University historian Beshara Doumani recounts in his history of soapmaking in Nablus that soapmakers used about 1000 pounds of qilw to make one batch (tabkha) of soap. He writes that,

Until the introduction of caustic soda in the 1860s, large numbers of bedouins from the Bani-Sakhr, Huwayatat, and Adwan tribes gathered barilla in the valleys of M`an, especially around Salt and Tadmur (Palmyra). In the summertime they piled these plants in towering stacks, burned them, gathered the ashes and coals into sacks, and carried them to Nablus in large caravans.

Burckhardt witnesses this process in 1812, and had this to say about the complex reciprocal obligations built around the qilw trade and other economic contacts with bedouins:

``The Arabs of the Belka [Balqa], especially the Beni Szakher [Bani Sakhr], bring here Kelly or soap-ashes, which they burn during the summer in large quantities: these are bought up by a merchant of Nablous, who has for many years monopolized the trade in this article. The soap-ashes obtained from the herb Shiman, of the Belka, are esteemed the best in the country…They are sold by the Arabs…but the purchaser is obliged to pay heavy duties upon them. The chief of the Arabs of El Adouan…exacts for himself five piasters from every camel load, two piasters for his writer, and two piasters for his slave. The town of Szalt [Salt] takes one piaster for every load, the produce of which duty is divided among the public taverns of the town. The quantity of soap-ashes brought to the Osha market amounts, one year with another, to about three thousand camel loads. The Nablous merchant is obliged to come in person to Szalt in autumn. According to old customs, he alights at a private house, all the expenses of which he pays during his stay; he is bound also to feed all strangers who arrive during the same period at Szalt; in consequence of which the Menzels [public taverns] remain shut; and he makes considerable presents on quitting the place. In order that all the inhabitants may share the advantages arising from his visits, he alights at a different house every year.''

Burckhardt‘s observation that three thousand camel loads were sent to Nablus annually in the early nineteenth century seems to be fairly accurate. Each tabkha of soap required at least 7 camel loads, or qintars of qilw. Because Nablus soap production ranged, at the very least, from 100 to 400 tabkhas a year, a minimum of 700 to 2,800 camel loads arrived in Nablus annually. Merchants from Nablus and the town of Salt also exported qilw to nearby soap- producing centers, such as Gaza, Jaffa, Lydda, Jerusalem, and Acre. Nablus merchants put conditions on the type and quality of qilw as well as on the time of delivery. According to Nimr, caravan shaykhs expected, in return, a certain percentage of the overall price as commission upon delivery, as well as some gifts in kind. For instance, Nimr claims that for every 100 camel loads, the caravan leader received money plus one large basket (quffa) of rice, as well as one ratel each of tobacco, sugar, soap, and coffee. He also received a cloak, a pair of boots, and a fur saddle blanket.

3. Barilla today

Barilla still grows abundantly across the Mediterranean, along saltwater shorelines in the United States, and elsewhere. Although its importance has diminished since the late 1800s with the introduction of industrially-produced caustic soda, barilla has found a new role in cuisine. In Italy, it is known as agretti and appreciated for its spinach-like flavor, while in the English-speaking world, it is called saltwort.

The historical significance of soda ash in the ancient Mediterranean world cannot be overstated. The earliest known soap recipe, dating back 4,500 years, was found on a clay tablet from modern-day Iraq and Kuwait, which were part of ancient Babylon. This recipe, which still informs artisanal soapmaking today, calls for ash, olive oil, and water.

Soda ash's linguistic legacy can also be traced in various words: sodium and soda come from the Arabic "sauda," while sodium's chemical symbol (Na) refers to natron, an ancient Egyptian version of soda ash used in papermaking, mummification, and soapmaking. The word "alkaline" originates from the Arabic "al-qaliy," meaning "burnt ashes." Barilla's historical importance is also reflected in local Spanish names like "almajo de los jaboneros" (soapmaker's bush) and "sauda maritima" (maritime soda plant).

The widespread use and commercialization of soaps during the Roman Empire continue to resonate in languages worldwide, with words like the Arabic "sabun," Spanish "jabón," French "savon," old Dutch "seepe," and English "soap" all stemming from the Latin term "sebum," which refers to tallow or animal fat.

Footnotes:

Sala Caja, Lidia. "La competencia terminológica: causas lingüísticas en el auge del término sosa y el declive de barrilla en los siglos XVIII y XIX." Asclepio (2003): 67-92.

4 comments

A bloke I cut cane with asked me once, where’s the Barilla..now I know he meant soap

Very interesting. While researching for my book on early whaling and sealing during the colonial period in Bass Strait (between Tasmania and Australia) in 1831 several loads of barilla were shipped from the islands of Bass Strait to Hobart for soap making. The island it came from is known as Green Island and is rather small and this would be the reason why barilla exports were only made during 1831. I have learnt something new… Thanks for your great little piece on the history of barilla. Best Wishes John Robertson. Western Australia.

Thank you for this very well done entry with lots of very interesting information.

Very interesting history. Thank your for providing this! I’m happy to have found this soap as it’s the only one that doesn’t dry my sensitive skin, but instead makes it clean, soft, and healthy.