Lime, Ash, and Olive: A portrait of the soapmaker's process

Share

LIME, ASH AND OLIVE

The World of Interiors (Magazine), May 2016

Aside from water there are just three ingredients in Nabulsi soap, acclaimed globally since the tenth century for its quality and purity. In its West Bank city of origin, north of Jerusalem, 40 manufacturers have now dwindled to three – and one of them is forging ahead with methods unchanged for a millennium.

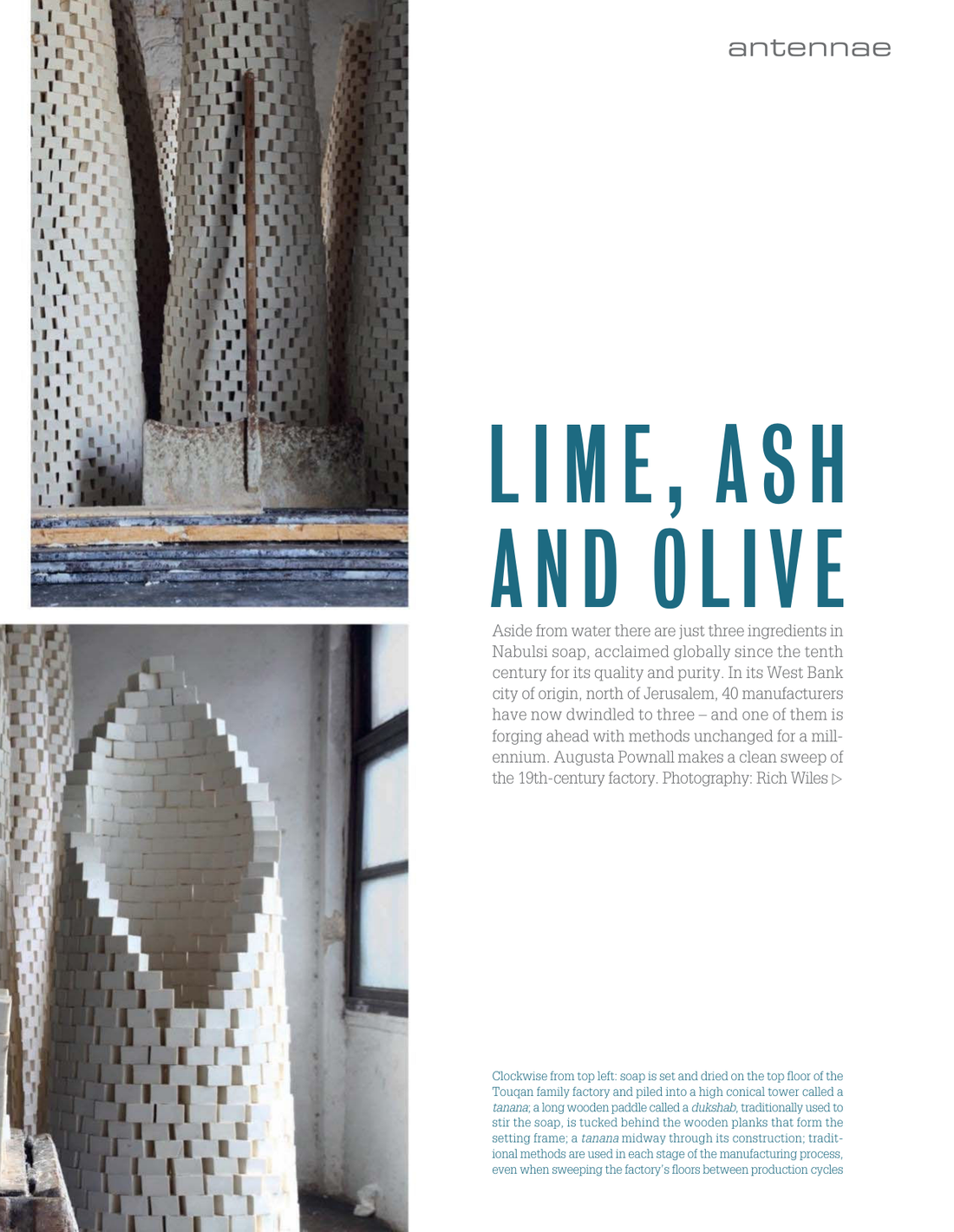

Clockwise from top left: soap is set and dried on the top floor of the Touqan family factory and piled into a high conical tower called a tanana; a long wooden paddle called a dukshab, traditionally used to stir the soap, is tucked behind the wooden planks that form the setting frame; a tanana midway through its construction; traditional methods are used in each stage of the manufacturing process, even when sweeping the factory’s floors between production cycles.

HAVE YOU EVER wondered what’s in the soap you wash your hands with? If it’s a pump-action bottle of Moisture Dream there will likely be any number of -ides, -ates and -enes alongside the surfactants that do the actual washing. Soap made in Nablus, a city in the West Bank about 50km north of Jerusalem, has very few ingredients: water, olive oil and a sodium compound made of ash and lime. The creamy-grey, odorless blocks are an entirely natural product so won’t irritate even sensitive skin and, surprisingly for those used to commercial brands, they don’t foam.

This fertile region, watered by natural springs, has been a base for soap production for over a thousand years. It’s said that even Elizabeth I (though hardly renowned for her skincare regime) was a fan of Nabulsi soap, as it is called in Arabic. Of the 40 or so factories in the city at the turn of the 20th century only three now remain, including the Touqan factory where these pictures were taken. Soap-making families guard their recipes zealously, but the basic premise is the same as it has always been. The ashes of barilla, a plant that grows on the salty banks of the River Jordan, are pounded into a powder. This is then mixed with locally sourced lime, and covered with hot water drawn from copper vats. The resulting concentrated alkaline solution is then returned to the vats, with the addition of olive oil produced in the region. This process is repeated perhaps 40 times over the course of a week while the oil absorbs the compounds, all the while being stirred continuously.

Master soap-makers know by taste the exact moment to pour the mixture into the wooden frames that run half the length of the factory floor. Too soon and it won’t dry properly; too late and it won’t cut into its trademark squares. At the factory, a grid of strings is plucked over the drying mass to mark the soap for the cutter’s hand. The squares of soap are then stamped with a seal distinct to each factory (Touqan uses two crossed keys). The two-story 19th-century factory building has thick stone walls to insulate it from sweltering summer heat and severe winters.

Things are not easy: military checkpoints around the city have made getting the ingredients in, and the finished soap out, harder than ever. ‘Before 2000, our factory used to produce 600 tons of soap annually,’ says the general manager at the Touqan factory. ‘Now we produce barely half that amount.’ The hollow towers of neatly spaced blocks rise higher than the men who stack them. At first glance you might not know that these were bars of soap; their strikingly modern geometric shapes could be an art installation. But their components represent a crucial industry of a city that finds itself caught in seemingly unending turmoil.

Top right: the soap is left to set for a day before it is stamped with the factory’s seal – a pair of crossed keys – and cut into blocks. Top left: the blocks rest before they are stacked into tananas to dry. Left: once ready, the finished item is wrapped in waxed paper by workers who can process between 500 and 1,000 bars an hour.

1 comment

I hope that after reading this article people see the importance of supporting Nablus soap production as both a show of appreciating a centuries-old artisan craft, and affirming the economic empowerment of Palestinians. This is some damn good soap. Buy it. Lots of it.